The “gold rush” era of microgreens—where anyone with a shop light and a bag of potting soil could claim to be a “farm entrepreneur”—has officially ended. In 2026, the market will have matured. The novelty of “tiny plants” has been replaced by a sophisticated global industry valued between $2.5B and $3B, characterized by high consumer expectations, tighter margins, and a demand for professional-grade reliability.

If you are looking at microgreens as a business today, the promise remains real: high-density production, rapid cash-flow cycles, and an ever-growing appetite for “functional foods.” However, the path to profit is no longer paved with green thumbs alone; it is paved with sales systems, food safety protocols, and unit economics.

Part I: The 2026 Market Landscape

The Shift from Garnish to Staple

In the early 2020s, microgreens were largely seen as a “chef’s garnish”—a sprig of purple radish to make a $40 steak look better. By 2026, the narrative has shifted. Driven by clinical research into sulforaphane (broccoli), polyphenols, and high-density Vitamin K, consumers now view microgreens as a nutritional insurance policy.

Market reports from firms like Mordor Intelligence confirm a steady 7–11% CAGR through 2030. This growth is fueled by three factors:

- Indoor Ag Tech Maturity: Efficient LEDs and automated climate controllers have become affordable for small-scale growers.

- Supply Chain Fragility: Traditional field-grown leafy greens (lettuce, spinach) face increasing climate volatility, making local, indoor-grown microgreens a more stable alternative.

- The “Food as Medicine” Movement: Retail customers are increasingly willing to pay a premium for “living” or ultra-fresh food that hasn’t spent five days in a refrigerated truck.

The Competition Reality Check

The “barrier to entry” is still low, which means your local market likely has three types of competitors:

- The Hobbyist: Sells occasionally at a Saturday market; often underprices everyone because they don’t track labor.

- The Industrial Grower: Huge vertical farms selling to national grocery chains; they win on price but lose on freshness and variety.

- The Professional Boutique (Your Goal): The grower who owns the local relationship, provides bespoke blends, and offers a “harvested-this-morning” quality that industrial farms cannot match.

Part II: The Economics of the “Perfect Tray”

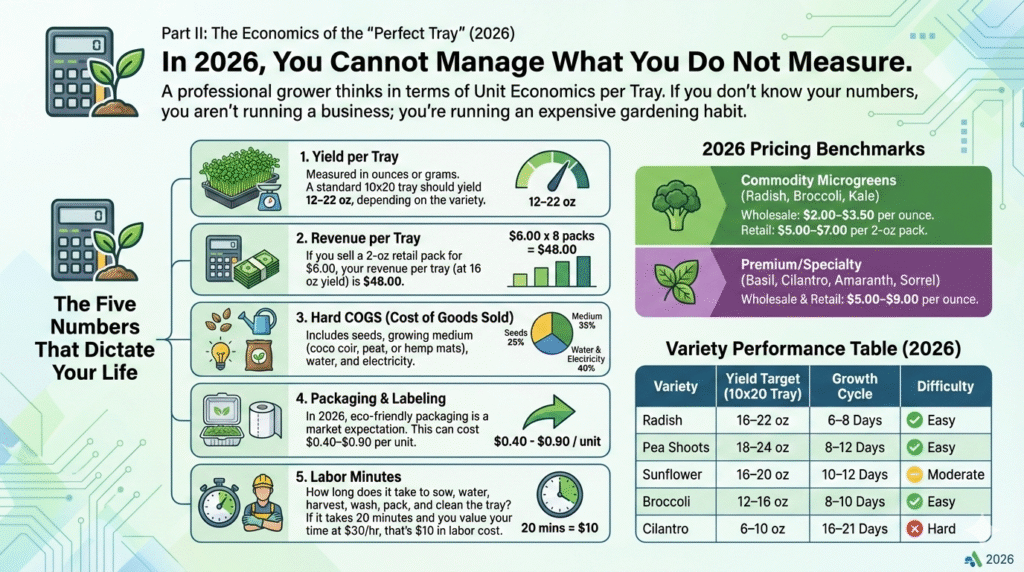

In 2026, you cannot manage what you do not measure. A professional grower thinks in terms of Unit Economics per Tray. If you don’t know your numbers, you aren’t running a business; you’re running an expensive gardening habit.

The Five Numbers That Dictate Your Life

To survive, you must track these five variables for every crop you grow:

- Yield per Tray: Measured in ounces or grams. A standard 10×20 tray should yield 12–22 oz, depending on the variety.

- Revenue per Tray: If you sell a 2-oz retail pack for $6.00, your revenue per tray (at 16 oz yield) is $48.00.

- Hard COGS (Cost of Goods Sold): This includes seeds, growing medium (coco coir, peat, or hemp mats), water, and electricity.

- Packaging & Labeling: In 2026, eco-friendly packaging is a market expectation. This can cost $0.40–$0.90 per unit.

- Labor Minutes: How long does it take to sow, water, harvest, wash, pack, and clean the tray? If it takes 20 minutes and you value your time at $30/hr, that’s $10 in labor cost.

🌿 Recommended Microgreens Supplies |

2026 Pricing Benchmarks

While local markets vary, the 2024–2025 benchmarks have solidified into a two-tier pricing system:

- Commodity Microgreens (Radish, Broccoli, Kale): $2.00–$3.50 per ounce (Wholesale) / $5.00–$7.00 per 2-oz pack (Retail).

- Premium/Specialty (Basil, Cilantro, Amaranth, Sorrel): $5.00–$9.00 per ounce.

| Variety | Yield Target (10×20 Tray) | Growth Cycle | Difficulty |

| Radish | 16–22 oz | 6–8 Days | Easy |

| Pea Shoots | 18–24 oz | 8–12 Days | Easy |

| Sunflower | 16–20 oz | 10–12 Days | Moderate |

| Broccoli | 12–16 oz | 8–10 Days | Easy |

| Cilantro | 6–10 oz | 16–21 Days | Hard |

Part III: The “Core 8” Strategy

In 2026, complexity is the enemy of scale. Many new growers try to offer 30 varieties and end up with massive waste and a chaotic schedule. The most profitable farms in 2026 focus on a Core 8 Menu plus a rotating “seasonal spotlight.”

The “Workhorses” (High Margin, High Volume)

- Radish (Rambo/Triton): The backbone of the business. It grows fast, looks beautiful (purple/green), and provides a spicy flavor profile that chefs love.

- Pea Shoots (Speckled): The highest yield-to-weight ratio. They are hearty, have a long shelf life, and can be used as a base for salads rather than just a garnish.

- Sunflower: The “crowd pleaser.” It’s nutty, crunchy, and filling. High caloric value makes it a legitimate food source.

- Broccoli: The “health” leader. Market it for its sulforaphane content. It is mild and easy to add to any meal.

The “Differentiators” (The Chef Magnets)

- Mustard (Wasabi/Scarlet): Provides a legitimate “kick.” Essential for Asian-fusion restaurants.

- Red Amaranth: Purely aesthetic. Its electric pink color makes it the most requested garnish for high-end plating.

- Arugula: Iconic peppery flavor. Chefs use this to replace standard baby arugula because the flavor is 10x more concentrated.

- Basil (Genovese/Lemon): Hard to grow (hates cold, prone to damping off), but commands the highest price point.

Part IV: Operational Excellence & Food Safety

The 2026 consumer is health-conscious and safety-aware. The FDA and local health departments have increased scrutiny on indoor farms. You must treat your grow room like a commercial kitchen, not a basement.

The Clean Zone Protocol

Professionalism starts with sanitation. You must implement a “Clean Zone” for harvesting and packing:

- Sanitization: All trays must be scrubbed and sanitized between uses (StarSan or dilute bleach).

- Water Management: Use only potable water. In 2026, most retailers require annual water test results to prove no E. coli or Salmonella contamination.

- Airflow: Proper CFM (Cubic Feet per Minute) exchange is non-negotiable. Stagnant air leads to mold, which leads to crop failure and lost revenue.

- Traceability: Every clamshell must have a Lot Number. This should link back to your “Sowing Log”—showing which seed batch was used and when it was harvested.

The “System” vs. The “Hobby”

A “system” means you know that every Monday at 8:00 AM you soak seeds, every Tuesday you sow, and every Thursday you harvest. If you “feel your way” through the week, you will fail. The 2026 grower uses automation for lighting and irrigation, allowing them to spend 80% of their time on Sales and Distribution.

Part V: Sales Channels That Actually Work in 2026

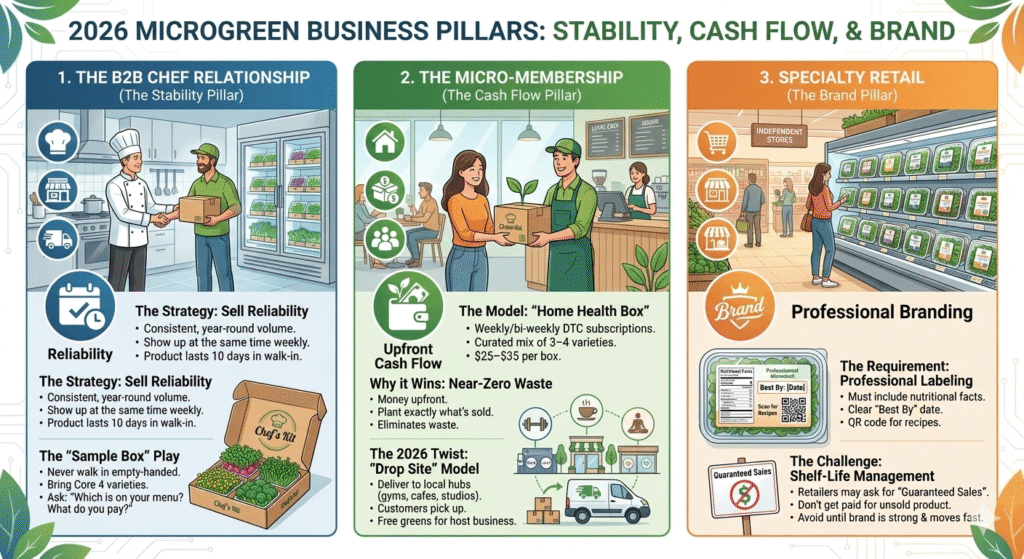

Where you sell is as important as what you grow. In 2026, the most successful growers diversify their income across three main pillars.

1. The B2B Chef Relationship (The Stability Pillar)

High-end restaurants, catering companies, and juice bars provide consistent, year-round volume.

- The Strategy: Don’t just sell “greens.” Sell reliability. Chefs care that you show up at the same time every week with product that lasts 10 days in their walk-in.

- The “Sample Box” Play: Never walk into a restaurant empty-handed. Bring a “Chef’s Kit” with your Core 4 varieties. Ask: “Which of these is on your menu currently, and what are you paying for it?”

2. The Micro-Membership (The Cash Flow Pillar)

Direct-to-Consumer (DTC) subscriptions are the “Holy Grail” of 2026 microgreen farming.

- The Model: A weekly or bi-weekly “Home Health Box.” Customers pay $25–$35 for a curated mix of 3–4 varieties.

- Why it Wins: You get the money upfront. You know exactly how much to plant, resulting in near-zero waste.

- The 2026 Twist: Use a “Drop Site” model. Instead of driving to 50 houses, deliver all boxes to a local gym, coffee shop, or yoga studio where customers pick them up. Give the host business free greens in exchange for the space.

3. Specialty Retail (The Brand Pillar)

Independent grocers, health food stores, and high-end butcher shops.

- The Requirement: Professional branding. In 2026, your label must include nutritional facts, a “Best By” date, and a QR code leading to recipes.

- The Challenge: Shelf-life management. Retailers will often ask for “Guaranteed Sales” (meaning they don’t pay for what doesn’t sell). Avoid this until your brand is strong enough to move off the shelf quickly.

Part VI: The 2026 Differentiation Playbook

How do you beat the guy down the street who just bought a rack from Costco? You sell outcomes, not plants.

1. The Power of Blends

Stop selling “Radish” and “Broccoli.” Start selling:

- “The Zesty Taco Topper”: Radish, Cilantro, and Mustard.

- “The Daily Detox”: Broccoli, Kale, and Red Cabbage.

- “The Kid-Friendly Crunch”: Pea Shoots and Sunflower (mild and sweet). Blends allow you to use up excess inventory and charge a 20% premium for the “convenience” of the mix.

2. The “Living” Advantage

If your local regulations allow it, selling “living” trays to high-end restaurants or home subscribers is a massive differentiator. The customer harvests it themselves, ensuring 100% freshness and zero shelf-life issues for you.

3. Educational Marketing

In 2026, you are a teacher as much as a farmer. Use social media to show:

- The Harvest: Show the cleanliness of your facility.

- The Plate: Show how to put microgreens on a pizza, in a smoothie, or atop an omelet.

- The Science: Share snippets about the nutrient density. People buy when they understand the “Why.”

Part VII: A Practical 90-Day Scaling Plan

If you are starting today (or rebooting a struggling farm), follow this roadmap to reach profitability by next quarter.

Days 1–30: The R&D Phase

- Setup: Build two 4-tier racks (standard 4-foot LED setup).

- Trial Runs: Grow 10 trays of each of the “Core 4” (Radish, Pea, Sun, Broccoli).

- Data Collection: Weigh every harvest. Calculate your average yield. If your broccoli yield is under 10 oz, adjust your seed density or light height before you ever talk to a customer.

Days 31–60: The Sales Blitz

- Targeting: Identify 20 local restaurants and 3 boutique grocers.

- Sampling: Deliver free sample kits. Focus on the “Standing Order” model. “I can deliver 5 lbs of Pea Shoots every Tuesday—would that help your kitchen workflow?”

- The Goal: Secure 5 consistent wholesale accounts. This covers your overhead (rent, power, seeds).

Days 61–90: Systemization

- Subscription Launch: Open 20 slots for a “Home Delivery” pilot program.

- Software: Implement a simple CRM or spreadsheet to track planting schedules.

- The Pivot: By day 90, you should be spending less time “playing with plants” and more time optimizing your delivery routes and customer retention.

The Bottom Line: Is it Worth it in 2026?

Yes—but only if you respect the math.

The microgreens business is a volume and consistency game. You cannot get rich off five trays in a spare bedroom. However, a well-run 20-rack operation in a 500-square-foot garage can generate $2,000–$5,000 in monthly net profit with disciplined systems.

The winners of 2026 are those who provide a professional solution to the modern problem of “empty calories.” By delivering ultra-fresh, hyper-local, nutrient-dense greens, you aren’t just selling a garnish; you are providing a vital component of the future’s food system.

Your Next Step

Every successful farm starts with a Yield Audit. Would you like me to design a custom Seed Density & Harvest Chart based on the specific tray size and lighting you plan to use? This ensures you don’t waste money on over-seeding or lose profit to thin trays.